While multi-warehouse commerce looks simple on paper—more locations, more flexibility, better coverage—it actually can be one of the most complex aspects of a fulfillment operation. Behind every sale there's a decision on which warehouse should ship the order, whether the shipment should split, which constraints apply to which products, and how those decisions stay in sync with ERP and WMS systems that remain the source of truth.

Therefore, the challenge is ensuring the commerce architecture can execute the fulfillment logic and constraints unique to your operating model.

TMO brings over a decade of Magento Development experience, building custom modules that translate complex operational rules into stable, scalable architecture.

We previously explained Why Magento Still Wins for Complex Business LogicLearn how Magento’s layered architecture and modular design enable complex commerce logic, safe customization, and long-term scalability.how Magento’s layered framework provides a robust foundation for advanced business logic and scalable customization across diverse operational scenarios. In this article, we’ll focus specifically on how that architecture supports multi-warehouse fulfillment logic in a way that lets businesses implement their own routing rules without accumulating technical debt.

The Fulfillment Challenge Behind Multi-Warehouse Commerce

Running multiple warehouses introduces operational complexity long before a shipment is dispatched. Each order forces the system to execute a series of allocation decisions that go far beyond simple shipping settings. At a minimum, the platform must determine:

- Which warehouse should fulfill the order based on region, capacity, or inventory profile.

- Whether the order should split across multiple locations, and when split logic is unacceptable.

- Which product-level constraints apply, such as hazmat limitations, chilled storage, or bulky-goods handling.

- Which payment or delivery restrictions apply by region (for example, Next-Day Delivery eligibility).

- Which carriers or service levels are available per warehouse.

- How ERP or WMS updates synchronize with the platform as the authoritative source of truth.

Every brand evaluates these fulfillment decisions differently, which makes flexibility essential. The platform needs a way to encode those rules without burying them inside templates, one-off extensions, or integration scripts that become difficult to maintain. Magento supports this by separating routing logic from both the presentation layer and the underlying inventory data.

This separation not only keeps the logic accessible and easy to adjust as fulfillment requirements evolve, but also allows the front-end to present availability, delivery options, and split-shipment scenarios accurately without carrying any of the operational complexity itself.

How Magento's Multi-Source Inventory (MSI) Works

Magento includes a multi-warehouse inventory framework out of the box called the Magento Inventory Project (formerly Multi-Source Inventory). It provides the structural model for defining allocation logic across real fulfillment scenarios, while the platform’s architecture ensures those rules sit in a clean, isolated layer that can evolve without destabilizing the system.

The same design underpins Magento’s Inventory Management APIs, which expose these components for headless storefronts, middleware, and ERP/WMS integrations. Below is an overview of the key components and how they support multi-warehouse operations:

| Component | Description | Function | What it Does |

|---|---|---|---|

| Source | A physical or virtual inventory location (warehouse, store, 3PL, marketplace node). | Holds actual stock quantities and location-specific attributes. | Allows Magento to understand where inventory is and apply location-level rules. |

| Stock | A logical grouping of sources mapped to a website or sales channel. | Controls which locations are eligible for each storefront. | Decouples sales channels from physical warehouses, enabling regional expansion without structural rewrites. |

| Reservation | A temporary “held” quantity created during checkout. | Prevents overselling in high-volume or multi-channel environments. | Keeps inventory accurate even when ERP/WMS updates are asynchronous. |

| Source Selection Algorithm (SSA) | The logic that determines which source(s) fulfill an order. | Selects fulfillment warehouse(s) based on rules, priorities, or custom logic. | Provides the decision layer for routing and can be replaced or extended to match real operational workflows. |

Together, these components give Magento the architectural scaffolding required for multi-warehouse fulfillment. MSI doesn’t decide how your routing should work. It ensures the system is capable of expressing your routing logic cleanly, without mixing rules into templates, checkout code, or brittle connectors.

Next, we’ll look at the different ways businesses implement multi-warehouse setups in Magento and how each approach affects long-term flexibility.

Ways to Implement Multi-Warehouse in Magento

Once the inventory architecture is in place, the question becomes how a business chooses to operationalize its multi-warehouse logic within Magento. The platform accommodates several implementation paths, each reflecting a different balance between configuration, customization, and long-term maintainability:

a) Native MSI (Out-of-the-Box)

Magento’s inventory framework ships with native support for multi-warehouse setups. Brands can configure Sources, assign them to Stocks, and use the default Source Selection Algorithm for basic allocation flows. This is suitable when fulfillment rules are stable and routing conditions are straightforward, for example:

- Limited number of warehouses

- Minimal or predictable routing variation

- Straightforward regional assignments

- ERP/WMS does not require granular control over allocation

Native configuration provides a reliable baseline, but it is rarely sufficient for fulfillment models with conditional logic or operational constraints.

b) Custom Modules on Top of MSI

For businesses with detailed fulfillment rules like regional restrictions, carrier constraints, capacity rules or delivery-promise logic, Magento's architecture allows the routing layer to be extended cleanly through custom modules that offer enhancements such as:

- Custom Source Selection Algorithms (SSAs) that evaluate proximity, capability, stock thresholds, or business-specific rules.

- Extended source attributes to encode operational constraints (e.g., chilled storage, oversized handling, regional carrier availability).

- Event-driven sync logic to align Magento reservations with ERP/WMS updates.

- Tailored reservation behavior for high-volume or multi-channel operations.

This approach keeps Magento as the primary decision engine while ensuring fulfillment logic lives in an isolated, maintainable layer that can evolve without affecting storefront or integration code.

c) Third-Party Extensions

When organizations want extended routing capabilities without the investment of building custom modules, third-party extensions offer pre-packaged logic for more advanced multi-warehouse scenarios.

These solutions typically enhance Magento’s inventory capabilities with additional allocation rules, warehouse controls, and operational workflows, It's an approach that works well when routing rules are moderately complex but still map reasonably well to a vendor-provided model.

Strengths:

- Accelerated implementation

- Predefined logic for common scenarios

- Lower initial development cost

Considerations:

- Logic is tied to the extension’s design

- Future adaptations may be constrained by vendor architecture

- Integration patterns may not match internal operational workflows

One example is Amasty’s Advanced MSI extension, which introduces expanded source-selection algorithms, warehouse prioritization tools, and more granular control over how Magento routes orders across inventory nodes.

Where Should Your Fulfillment Logic Live?

The choice between native configuration, custom modules, or extensions ultimately depends on a broader architectural decision: whether Magento should own the allocation logic or consume it from ERP, WMS, or a dedicated routing service.

Magento is fully capable of acting as the allocation engine, but businesses with highly centralized backend systems or multi-node orchestration may prefer to externalize routing decisions. Magento’s modular structure supports both models without compromising stability.

5 Multi-Warehouse Fulfillment Scenarios

Multi-warehouse setups introduce different routing and allocation requirements depending on how a business operates. The following scenarios illustrate the types of fulfillment models that Magento’s inventory structure can support, and how the platform handles practical conditions that appear in day-to-day operations.

1) Region-Based Fulfillment Logic

Organizations that operate across multiple markets need routing that respects regional realities: different tax zones, carrier availability, COD rules, regulatory constraints, and varying delivery expectations.

- Stocks map cleanly to regional websites or storefronts.

- Sources can be grouped or separated based on geography.

- Custom SSAs allow businesses to encode location-based logic without rewriting checkout flows.

This keeps regional expansion predictable without rebuilding the fulfillment layer each time a new market goes live.

2) Split vs Consolidated Shipments

Some businesses want to avoid split shipments at all costs; others treat them as a standard operating practice. Rules often depend on order value, delivery promise, product type, or region.

- MSI provides the structure to determine when split shipments are acceptable.

- Custom routing logic can prioritize consolidation or enable exceptions under specific conditions.

- Presentation and logic remain separated, so UI changes do not affect routing behavior.

This supports a consistent customer experience without hard-coding fulfillment decisions into the front-end.

3) Inventory Health and Priority Rules

Many operations need to route based on stock profiles: selling ageing or promotional inventory first, preserving best-sellers, or diverting fragile stock to specialized hubs.

- Warehouse attributes can be extended to describe stock profiles.

- Custom SSAs can prioritize warehouses based on ageing, safety stock, or promotional inventory.

- Reservation logic ensures accurate availability across channels.

Magento becomes capable of expressing the nuances behind inventory strategy, not just showing quantities.

4) Omnichannel and Store-Fulfilled Orders

Retailers often use stores as fulfillment nodes for ship-from-store or click-and-collect. These setups create more dynamic routing conditions than traditional warehouse models.

- MSI models stores as independent sources with their own stock levels.

- Routing logic can determine when stores should fulfill or when central warehouses take priority.

- Rules can reflect in-store capacity, inventory freshness, or store-based labor constraints.

This allows omnichannel models to evolve without replatforming the fulfillment engine.

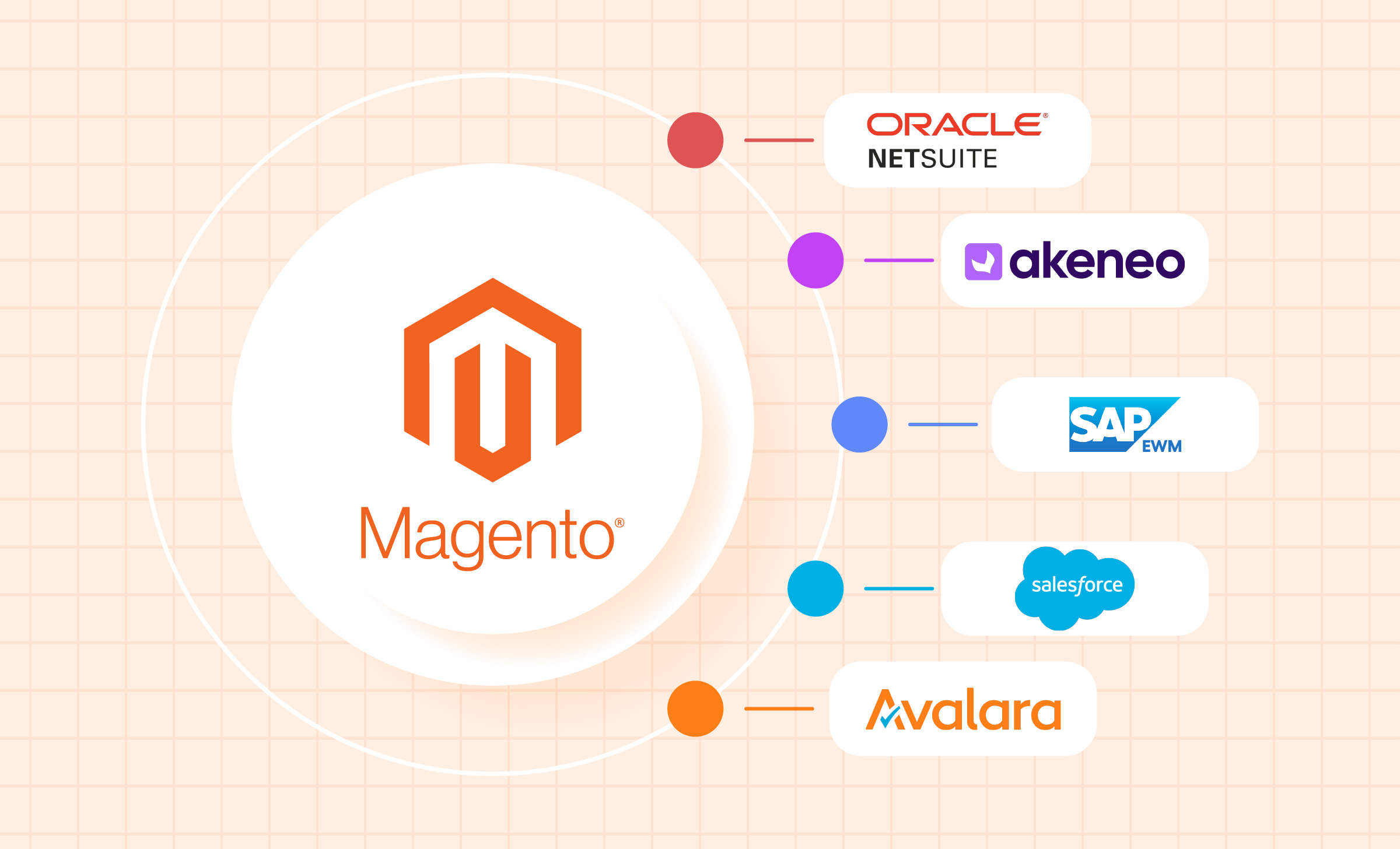

5) Marketplace and 3PL Fulfillment

Businesses that rely on Amazon FBA, Lazada FBL, Shopee FBM+, or 3PL networks need routing logic that accounts for external inventory sources while keeping Magento as the unified customer-facing layer.

- External nodes can be modeled as MSI sources or integrated as part of routing logic.

- Custom modules or extensions can prioritize marketplace or 3PL sources under certain conditions.

- Decisions remain transparent in Magento even when fulfillment happens elsewhere.

The architecture accommodates hybrid fulfillment strategies without introducing brittle dependencies.

Customizing Magento's MSI

MSI gives Magento the structural foundation for multi-warehouse fulfillment, but most organizations eventually encounter scenarios where native routing isn’t sufficient. This is where custom modules become valuable, allowing teams to encode business-specific rules in a contained, discoverable, and replaceable way. If priorities shift next year, the changes occur within the same logical module, not across scattered templates, custom scripts, or third-party integrations.

This isolation is what makes Magento sustainably extensible for logistics-heavy operations. It enables continuous evolution of fulfillment rules without compromising system stability, performance, or maintainability. Custom modules typically extend MSI in a few key areas:

| Customization | Examples |

|---|---|

| Source Selection Algorithms (SSAs) | - Distance-based routing - Avoiding split shipments - Prioritizing ageing stock - Preferring certified warehouses for hazmat items - Capacity-aware allocation |

| Warehouse / Source Attributes | - Flags for chilled storage, bulky-goods handling, express-eligible, or regional carrier availability - Custom cut-off times - Operational capabilities |

| Event-Driven Sync Logic | - Triggering ERP/WMS updates when reservations change - Adjusting stock levels after partial fulfillments - Recalculating availability when inbound shipments arrive |

| Reservation and Allocation Behavior | - Clearing stale reservations - Partial reservations in high-volume environments - Temporarily diverting orders during warehouse maintenance or downtime |

| Front-End Data Exposure Rules | - Showing warehouse-specific delivery options - Revealing or hiding express shipping based on source capabilities - Surfacing accurate ETAs tied to the selected fulfillment node |

The customization areas in the table reflect how multi-warehouse operations function in practice. Routing rarely depends on stock levels alone, so many teams adjust the Source Selection Algorithm to account for proximity, warehouse capability, or product constraints. Warehouses themselves vary in what they can handle, which is why extending source attributes becomes useful for modeling conditions such as chilled storage, oversized handling, or regional carrier limitations.

Inventory also needs to stay aligned with ERP or WMS systems, making event-driven sync logic an important part of keeping availability accurate. On the customer-facing side, some operations refine reservation behavior to better manage high-volume or partial fulfillments, while others surface warehouse-specific delivery options or ETAs so the storefront reflects real fulfillment conditions.

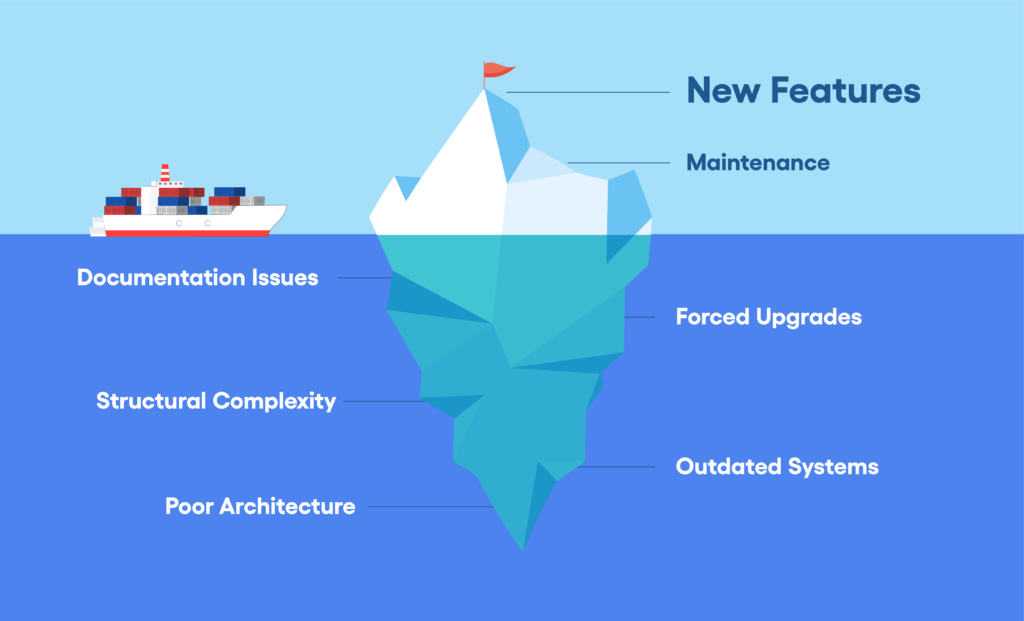

Key Considerations for Multi-Warehouse Setups

Magento’s inventory architecture provides a strong foundation, but multi-warehouse fulfilment often involves conditions that extend beyond what a commerce platform should manage on its own. Understanding these boundaries helps teams design implementations that remain stable as operational complexity grows. Key considerations include:

- SLA or ETA-based routing: Allocation rules driven by delivery promises, cut-off times, or carrier capacity are not native to Magento. These scenarios generally require custom SSAs or an external orchestration layer that calculates service levels before Magento assigns a source.

- Complex multi-node networks: When fulfilment spans warehouses, stores, 3PL hubs, and marketplace nodes, routing rules frequently exceed what a shopping cart should govern. An Order Management System (OMS) becomes valuable for reallocation, partial shipments, cancellations, and exception handling.

- Dependency on ERP/WMS data quality: Magento can only allocate correctly if upstream systems provide timely and accurate stock updates. High-volume environments and asynchronous integrations increase the risk of stock drift unless inventory governance is carefully managed.

- Performance considerations in large catalogs: In operations with extensive product ranges or heavy concurrent traffic, MSI queries and custom SSAs add processing overhead. Proper indexing, caching, and module design are essential to maintain performance.

- Third-party extension architecture: Extensions can accelerate deployment, but they also bring their own design assumptions. Future routing changes may be constrained by how the extension models warehouses, priorities, or carrier rules.

- Ownership of fulfillment logic: The architecture supports adaptability, but fulfillment rules still require clear operational ownership as business requirements evolve. Without governance, even a well-structured implementation can degrade over time.

Magento’s strength lies in its ability to express complex, multi-warehouse logic cleanly. But like any architecture, its effectiveness depends on how well the surrounding systems like ERP, WMS, OMS, integrations, and operational processes complement its design.

Designing Complex Magento Fulfillment Flows with TMO

Multi-warehouse fulfilment introduces operational rules that differ widely across industries, from regional routing constraints to warehouse capabilities, delivery-promise expectations, stock-allocation priorities, and system dependencies.

Magento’s ability to tailor these rules makes it a dependable option for logistics-heavy commerce models and for organizations operating across multiple nodes or markets. As operations expand across warehouses, carriers, and fulfillment partners, this architecture becomes a strategic advantage: teams can evolve routing behavior, integrate new nodes, adjust constraints, or refine allocation priorities without rewriting the foundation of the system.

Whether you’re expanding to new warehouses, redesigning your fulfillment flows, or assessing if Magento can support the complexity of your operation, at TMO we can build a custom solution that adapts to your specific logistics model. Reach out to us for a personalized discussion.